How to Handle Custom Engraving Orders

Handling custom engraving orders for granite monuments and tombstones requires a coordinated approach across manufacturing, material selection, customization, quality control, and international shipping. Buyers such as importers, wholesalers, distributors, and funeral supply companies benefit from clear processes that minimize risk, control costs, and ensure memorials meet specification and regulatory requirements.

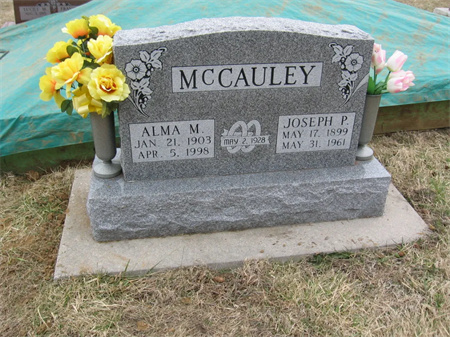

Initial order intake should capture precise specifications, including monument dimensions, granite type and color, surface finish, inscription text, artwork or photo etchings, font choices, installation requirements, and delivery terms. Suppliers typically translate buyer requirements into CAD drawings or templates and provide digital proofs for approval. A formal approval process—signed sketches or email confirmations—reduces the risk of errors before production commences. For complex designs, consider requesting a small sample engraving or a photographic mock-up to verify font scale, contrast, and image fidelity.

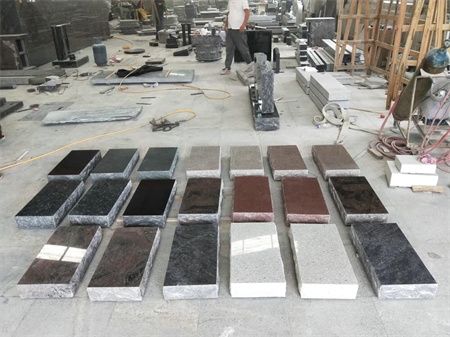

Material selection is critical for longevity and appearance. Granite varieties differ in porosity, grain structure, frost resistance, and color stability. Common options include deep-black granites for high contrast inscriptions, lighter grey or pink granites for traditional markers, and coarse-grained varieties for rustic styles. Discuss expected weathering, polish retention, and maintenance with your supplier, and specify any performance requirements such as freeze-thaw resistance for northern climates. Grade and batch identification should be recorded so that large orders use matched slabs to ensure consistent color and veining.

Manufacturing techniques influence both the aesthetic outcome and long-term durability of inscriptions. Sandblasting with rubber or metal stencils remains a widely used method for deep, permanent lettering. CNC engraving offers precision for raised letters and relief work, while laser etching and diamond-bit carving are preferred for detailed photographic reproductions and fine shading. Post-engraving treatments such as paint or epoxy fill, gilding, and sealing should be specified in the order. Polishing and edge profiling—bevel, bullnose, or chamfer—affect the final look and must align with installation requirements and cemetery regulations.

Quality control should be structured and documented. Implement in-process inspections at critical stages: template fitting, surface prep, engraving depth and alignment, and final finish. Measure tolerances for dimensions and flatness, verify inscription accuracy against approved proofs, and assess adhesion and color of any fills. Photographic records of each completed monument before packing provide evidence for acceptance and are essential in the event of claims. For larger or high-value orders, third-party inspections (for example, SGS or an independent pre-shipment inspection agent) can provide additional assurance.

International shipping of finished monuments introduces logistical considerations. Choose appropriate incoterms (FOB, CIF, DDP) and ensure accurate export documentation including commercial invoice, packing list, certificate of origin, and HS codes for customs clearance. Robust packaging is essential: export-grade wooden crates with internal bracing, foam or timber supports, edge protectors, rust inhibitors for metal fittings, and clear labeling reduce breakage during transit. Container loading plans should account for weight distribution and secure lashing to prevent shifting. Insure shipments and retain pre-shipment photos and inspection reports to support cargo claims if damage occurs.

Clear communication, standardized documentation, and adherence to manufacturing and shipping best practices will reduce delays and disputes. Establishing these procedures with your supplier will help ensure that custom engraved monuments meet buyer expectations and arrive intact for installation.

In conclusion, successful handling of custom engraving orders relies on precise specifications, appropriate granite selection, suitable engraving techniques, rigorous quality control, and secure international shipping practices to meet the needs of monument importers and distributors.

Copyright © Huian Boda Stone Co.,Ltd All rights reserved.

ipv6 network supported