MOQ Requirements for Wholesale Tombstones

Minimum order quantities (MOQs) for wholesale tombstones vary widely depending on factory capabilities, material choice, and the degree of customization required. For overseas importers, wholesalers and funeral supply companies, understanding how MOQs are determined helps in planning product portfolios, negotiating prices, and managing inventory. Factors such as stock availability, material type (granite vs. marble vs. engineered stone), production processes, and finishing requirements all influence the minimums a supplier will accept.

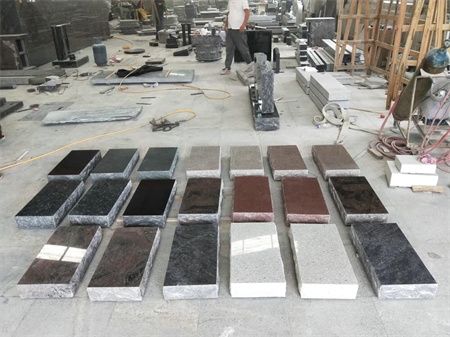

Manufacturers commonly set lower MOQs for standard, stock designs that are already cut and polished, while custom-designed granite monuments and memorials typically carry higher minimums. Standard tombstone models and slab options may be available in small quantities—sometimes as few as one to ten pieces per style—because they can be taken from existing stock. Custom shapes, bespoke engraving, inlaid bronze vases, or complex multi-piece monuments generally require larger runs to justify the tooling, CNC programming, and manual labor involved; in these cases MOQs can rise to dozens or more per design. Importers should request clear MOQ policies for both stock items and customized projects before committing to samples or production runs.

Material selection plays a central role in MOQ and pricing. Granites with steady supply and uniform dimensions are easier for factories to work with and often allow smaller minimums. Rare or imported stone types can necessitate ordering full slabs or containers, increasing the effective MOQ. Quality specifications—such as density, porosity, color consistency, and surface finish—should be agreed upon in writing. For many B2B buyers, approving material samples or short pre-production runs helps minimize risk while confirming that polish, honing, or sandblasted finishes meet cemetery and cultural requirements.

Customization options—engraving depth, epitaph fonts, laser etching, gold leaf inlay, bronze plaques, and custom bases—affect both lead time and cost. CNC cutting and computerized sandblasting improve consistency on larger orders, while detailed hand-carved work requires more skilled labor and typically results in higher minimums and longer production windows. Factories may charge one-time tooling or pattern fees for novel designs; clarifying whether these charges are amortized across units is essential for accurate cost calculations.

Quality control is critical for monuments and memorial products that must stand outdoors for decades. Reputable suppliers implement multi-stage inspection plans, including raw material checks, dimensional verification after cutting, finish inspections for polish and coating, and final packing inspections. Many exporters welcome third-party inspections or provide photographic and video evidence throughout production. ISO certification, material test reports, and references from other international buyers are useful due diligence items for distributors and funeral supply companies.

International shipping logistics also influence MOQ decisions. Export packaging standards—ISPM 15-compliant crates for wooden packaging, reinforced steel bands, waterproof wrapping, and internal cushioning—protect heavy stone items during container transport. Container space efficiency, measured in cubic meters per 20ft or 40ft container, determines how many tombstones fit per shipment, effectively setting a practical MOQ for ocean freight. Buyers should confirm freight terms (EXW, FOB, CIF), estimated lead times, and necessary documents such as commercial invoices, packing lists, certificates of origin, and any required local permits.

Clear communication on MOQs, materials, customization options, quality control processes, and shipping arrangements enables wholesalers, distributors, and funeral service suppliers to make informed purchasing decisions and manage inventory effectively. In conclusion, negotiating flexible minimums often depends on project planning, willingness to accept stock versus custom pieces, and coordination with manufacturers on production and logistics.

Copyright © Huian Boda Stone Co.,Ltd All rights reserved.

ipv6 network supported