Inside a Chinese Headstone Factory

For importers, wholesalers, distributors, and funeral supply companies evaluating suppliers, understanding the production environment behind granite monument and tombstone manufacturing helps set realistic expectations for lead times, quality, and logistics. A typical Chinese monument factory combines large-scale stone processing capabilities with skilled finishing and export infrastructure tailored to international buyers of memorial products.

Raw material sourcing begins at the quarry. Factories commonly work with domestic and imported granite varieties, selecting blocks by color, grain, and density to match specification sheets. Material verification includes slab inspection for cracks, porosity testing, and certificates of origin. Accurate material selection is critical for long-term durability of outdoor memorials exposed to freeze-thaw cycles and acid rain.

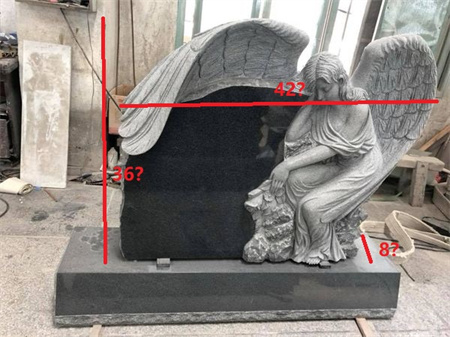

Primary fabrication relies on automated and semi-automated equipment. Large sawing and CNC cutting machines produce precise profiles and reduce waste on complex shapes. Polishing lines with progressively finer abrasives produce the finished surface, while sandblasting and laser engraving systems create epitaphs, portraits, and textures. Hand carving and final detailing remain essential for custom headstones and sculptural elements where artisan skill determines the quality of letters, reliefs, and fine edges.

Customization is a core service for overseas buyers. Most factories provide CAD drawings and digital proofs for approval, allowing adjustments to dimensions, fonts, languages, and iconography before production. Custom headstones may include inlays, bronze fittings, or dual-language inscriptions. Sample manufacturing — typically at a small additional cost — is offered for new designs or when color matching is critical for family requests or cemetery regulations.

Quality control is integrated at multiple stages. Incoming stone receives an initial inspection; dimensional tolerance checks occur after cutting; surface finish and inscription accuracy are verified post-polishing. Many facilities maintain written inspection protocols and can provide photographs or video of checks on request. Tests for metal components often include salt-spray resistance and adhesion tests for coatings. ISO or other factory certifications, when available, can support a buyer’s vendor qualification process but do not substitute for order-specific quality agreements.

Finishing includes assembly of multi-part monuments, installation of metal vases and plaques, and application of sealants or protective treatments. Protective packaging for export is critical: monuments are typically wrapped in foam and sealed in reinforced plywood crates or mounted on pallets to withstand container movement. Export packing often accounts for international shipping constraints and cemetery handling requirements, including marking fragile areas and providing assembly instructions.

International shipping logistics are handled daily by experienced exporters. Options include FCL or LCL container loading, with FOB terms commonly used in contracts. Proper container loading practices — bracing, blocking, and weight distribution — reduce risk of damage. Standard customs documentation includes commercial invoices, packing lists, bills of lading, and certificates of origin; some buyers also require phytosanitary or fumigation certificates for wooden crates. Understanding tariff classifications and import regulations in the destination country expedites clearance and reduces demurrage risks.

Turnaround times vary with order size, customization level, and seasonal demand. Effective communication, clear technical drawings, and defined acceptance criteria are essential for smooth transactions. For businesses sourcing memorial products internationally, verifying manufacturing capabilities, quality control procedures, and export experience provides a practical basis for supplier selection.

In conclusion, a professional monument manufacturer combines reliable granite sourcing, advanced stone processing, flexible customization, and disciplined quality control with export-focused packing and shipping processes to meet the needs of international buyers in the tombstone and memorial products market.

Copyright © Huian Boda Stone Co.,Ltd All rights reserved.

ipv6 network supported