What Importers Should Know About Memorial Regulations

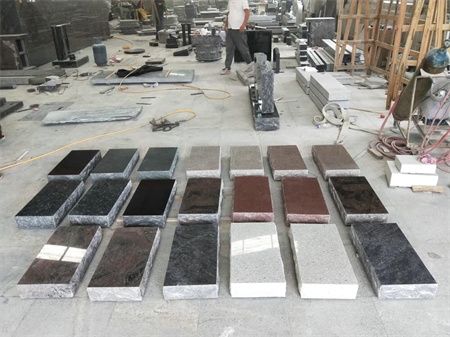

International buyers of granite monuments, headstones, and tombstones must balance aesthetic requirements with a complex regulatory landscape. Municipal and cemetery authorities commonly impose restrictions on size, height, base dimensions, and allowable materials for burial markers and mausoleums. Prior to production, importers, wholesalers, and distributors should obtain the cemetery’s specification sheet or local permit requirements to ensure that memorial designs, from upright headstones to flat burial markers, meet installation and long-term maintenance standards.

Manufacturing processes for memorials include block cutting, CNC profiling, sandblasting, laser etching, and hand finishing. Material selection—typically granite, marble, and bronze components—affects durability, appearance, and compliance. Granite is often preferred for its weather resistance; relevant material standards such as ASTM C615 (granite dimension stone) provide useful technical benchmarks. For bronze plaques and fittings, verify casting tolerances and patination procedures to reduce on-site restoration needs. Documenting production techniques and material certificates aids transparency during customs clearance and buyer inspections.

Customization is a key selling point in the memorial trade, but personalization introduces regulatory and technical considerations. Inscriptions, religious symbols, and emblems may be subject to cemetery approval or local laws governing public monuments. Photo applications, ceramic inserts, and laser-etched imagery require validated processes to ensure longevity and legibility. Provide clients with clear proofs and production mock-ups, and retain records of sanctioned designs to streamline permit approvals and reduce revision-related delays.

Robust quality control is essential to minimize rework and protect reputation across international markets. Implement dimensional inspections, polish-level checks, adhesion tests for inlays, and verification of inscription accuracy before shipment. Quality management systems such as ISO 9001 can support standardized procedures and traceability. Pre-shipment inspections, either in-house or via third-party inspectors, should include packaging integrity assessments and functional tests for anchors, dowels, and mounting hardware to confirm they meet cemetery foundation requirements.

International shipping of heavy stonework poses unique logistical and regulatory challenges. Correct classification with Harmonized System (HS) codes, accurate commercial invoices, certificates of origin, and packing lists are prerequisites for customs clearance. Wooden crates and pallets must comply with ISPM 15 phytosanitary treatment regulations to avoid fumigation delays or quarantine holds. Container loading should prioritize correct weight distribution, use of dunnage, and secure strapping to prevent movement; ocean freight options typically include FCL for large consignments or consolidated LCL shipments for smaller orders. Arrange marine insurance and coordinate with local freight forwarders familiar with cemetery delivery constraints, crane limits, and inland handling needs.

Understanding international compliance requirements — from chemical regulations like REACH that may affect adhesives or coatings to local cemetery statutes — reduces unexpected costs and lead times. Providing detailed material specifications, production photos, and supporting certificates expedites approvals and strengthens buyer confidence. By integrating rigorous manufacturing standards, clear customization workflows, comprehensive quality control, and compliant shipping practices, importers and distributors can better manage regulatory risk and deliver durable memorial products to their customers.

Copyright © Huian Boda Stone Co.,Ltd All rights reserved.

ipv6 network supported